Maxima

Acrylic decorative enamel «Touch of Magic»

Specification

The enamel provides permanent color and gloss. It obtains high resistance to mechanical load, abrasion and washing with detergents. It dries quickly and has no strong odor. It has advanced resistance to weather effects, UV-rays and moisture. It has perfect adhesion with coated surface.

Decorative enamel with the "pearl" effect is an idea for decorative finishing of walls, ceilings, window frames, doors, furniture, forge, elements of decoration (molding, foot stalls etc.), decorative coating of different surfaces.

Different colors of the product are allowed to mix.

Sphere of application

It is intended for coating of new and previously coated wooden, undercoated metal, mineral (plaster, concrete, mortar, brick, gypsum), glass, polystyrene foam and textured wallpapers.

Tinting

It can be tinted manually with Pigment Concentrate Farbex Color, other waterborne coloring pastes or with a coloring machine acc. to NCS color range and others.

Content

Technical data

| Consumption standard of 1 layer | 110-160 g/m2, depending on the way of application and type of surfaces. |

| Thinner | Water . Apply with a brush, a sponge and other special tools, which are necessary to create decorative effect. |

| Application | Apply with a brush, a sponge and other special tools, which are necessary to create decorative effect. |

| Drying period (23 °С, 50% RH) | 1 hour. Drying period increases if the temperature is getting down and relative air humidity is increasing. |

| Solids content (DSTU ISO 3251) |

About 36-38 %, depending on the color. |

| Density (DSTU ISO 2811-1) | About 1,1-1,14 g/сm3, depending on the color. |

| Hardness (DSTU ISO 1522) | ≈ 50 sec. |

| Resistance to washing | Resistant to intensive repeated washing (1st class acc. to SSU U EN 13300) |

| Non-volatile matter by volume (DSTU ISO 3233) |

- |

| VOC content (ISO 11890) | - |

| Warranty period | 24 months from the date of manufacturing (at the temperature from +5 °С till +35 °С) |

| Packaging | 0,1 kg, 0,25 kg, 0,5 kg |

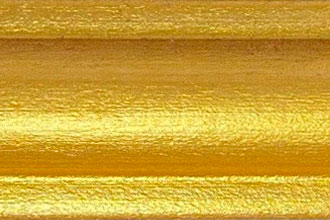

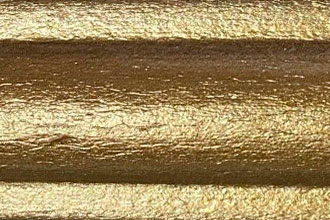

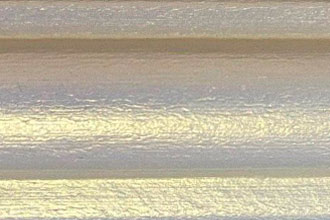

Color

Application instruction

-

1. Surface preparation

The surface shall be hard, clean, and dry. Clean thoroughly of dirt, grease, dust, rust, old paint coatings, and other dirt.

Clean dirty areas with a dry brush.

To receive a smooth surface without visible places of old coatings (paint or varnish), it shall be totally removed from the surface in mechanical (with a scratcher, a floor scrubber), thermal (a hot dryer, infra-red rays) or chemical way (paint removing treatments).

Surfaces, previously coated with oily or alkyd paints, shall be sanded for better adhesion.

Defected surfaces (holes, rends, cracks) shall be filled with Putty for wood ТМ Farbex.

Dub small defects of mineral surface with finish putty TM "Farbex".

The metal surface shall be thoroughly cleaned from rust with a wire brush and polished with sandpaper.

Plastered surfaces shall be polished until smooth and removed from the dust.

2. Priming

Previously coated wooden surfaces do not require undercoating.

Previously uncoated wooden surfaces shall be primed with Acrylic wood Primer TM Maxima.

Uncoated absorbing mineral surfaces shall be primed with Deep-penetrating acrylic primer "Base" TM Maxima.

Uncoated metal surfaces shall be primed with anticorrosion primer GP-021 TM Farbex.

3. Applying of finishing layer

The product shall be carefully stirred. Enamel is ready for use, if needed dilute it with water.

Application is performed at the temperature from + 5 °С till + 35 °С and relative air humidity no more than 80%.

The recommended application of the product is 1-2 layers. The next layer shall be applied not earlier, than in 2 hours.

Do not apply under direct sunlight, strong wind, frost and atmospheric precipitation. After the coating is applied it shall not be affected by atmospheric precipitation and sub-zero temperatures before finishing coating for 24 hours.

4. Tool cleaning

Clean tools with water after application.

References

Tips

Як самостійно оновити старі меблі

Якщо вам набрид старий інтер’єр, не обов’язково робити ремонт. Достатньо оновити меблі. Не потрібно купувати нову шафу, комод, стілець чи крісло. Ми поділимося з вами декількома порадами, як перефарбувати меблі, при цьому зберегти свої кошти. Основна послідовність, якої ми рекомендуємо …

Acrylic enamels Maxima

Acrylic enamelsповністю

Flow calculator

Consumption standard of 1 layer

When calculating the area to be painted, you need to subtract the area that will not be painted. (windows, doors, etc.)

Paint consumption may vary depending on dilution and uniformity of application of the paint.