Specification

Two-component epoxy enamel creates a hard coating that is resistant to mechanical loading, chemical impacts, temperature fluctuations, and intensive repeated washing. It effectively protects the base surface against wear and dust formation, lessens the porousity of the surface, and simplifies care. It provides perfect adhesion.

Sphere of application

The enamel is intended for decorative and protective coating of concrete, cement, and other hard mineral surfaces, especially in manufacturing workshops, garages, trade and store premises, parking areas, and similar locations. The enamel is good for coating ceramic slate, stone and previously primed metal surfaces. It is used for interior works.

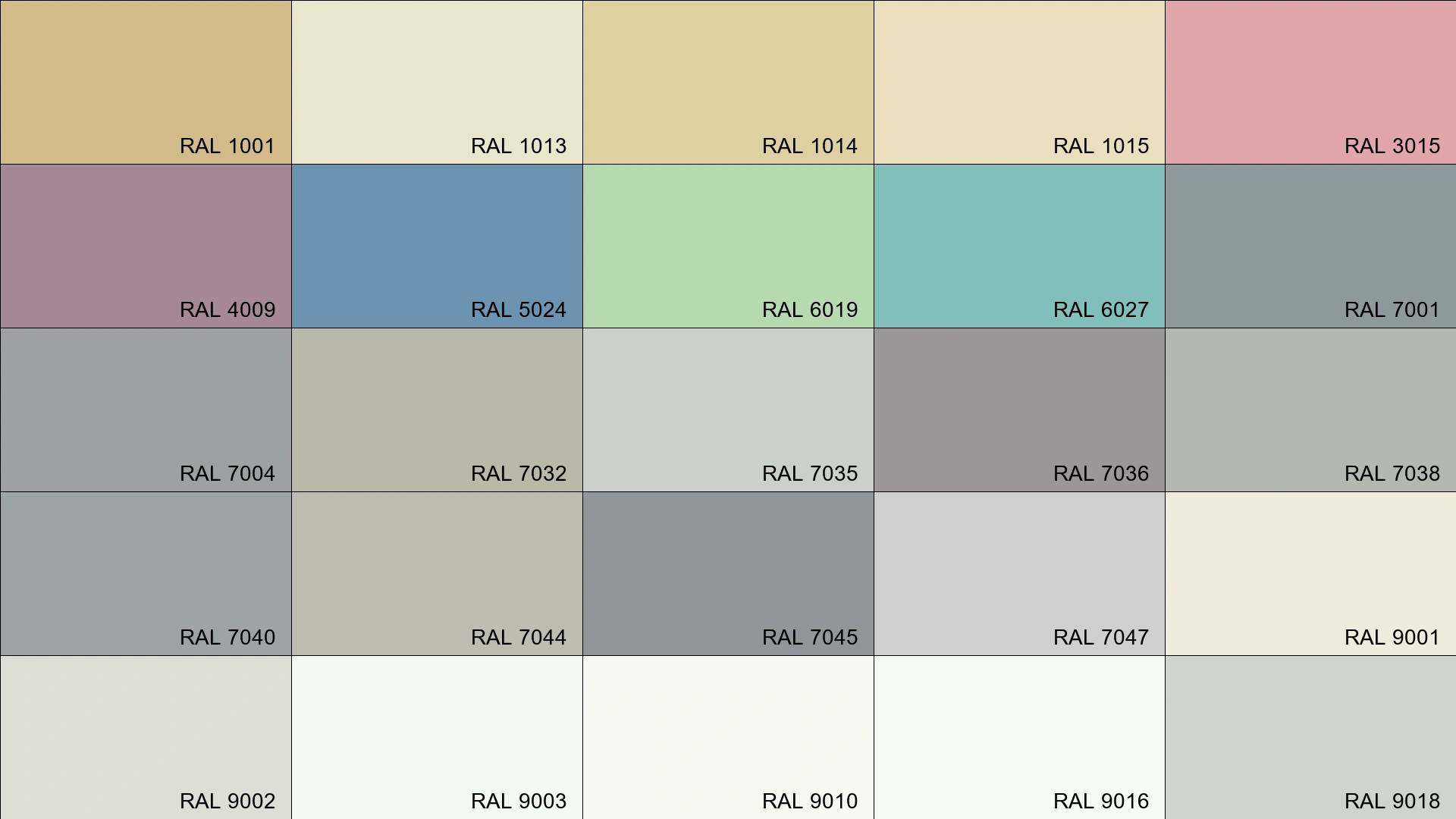

Tinting

It can be tinted in a tinting machine according to the RAL catalog (1001, 1013, 1014, 1015, 3015, 4009, 5024, 6019, 6027, 7001, 7004, 7032, 7035, 7036, 7038, 7040, 7044, 7045, 7047, 9001, 9002, 9003, 9010, 9016, 9018).

For a definite color, it is necessary to tint only the BASE. ACTIVATOR is not recommended for tinting.

Content

Component A (Activator): modified epoxy resin.

Technical data

| Product preparation (mixing of components) |

-Epoxy enamel consists of two components: a BASE and an ACTIVATOR. Component B (Base) is the base of two-component epoxy enamel for concrete surfaces TM "Maxima" Component A (Activator) is the component that activates the process of enamel polymerization after mixing with the base. Mix ration Base : Activator = 5:1 (according to mass). The Base and Activator must be used only together. Using them for other purposes without the recommendations of specialists from POLYSAN company is prohibited. |

| - | Ready-to-use enamel can be used during 1 hours (at the temperature +20 °C) from the moment of preparation! |

| Consumption standard of 1 layer | 100 – 200 g/m² , depending on the type of the surface and method of application |

| Thinner | Water

. Up to 10% dilution of the total mass is allowed.

Add water only to ready-to-use mixture (component A + component B)." |

| Application | Apply with a roller, a brush or a spraying gun. |

| Drying period (23 °С, 50% RH) | Dry to touch - 8 hours. Apply all subsequent coats at 12 hour intervals. Moderate exploitation - 24 hours. Full exploitation - 10 days. Drying period increases when the temperature gets down and relative air humidity gets higher and depends on the consumption (thickness of coat) of the enamel. |

| Solids content (DSTU ISO 3251) |

50±2 % (Base, component B) minimum 95 % (Activator, component А)) 58±2 % (Mixture А+B ) |

| The degree of milling (SSU ISO 1524) | max 30 microns |

| Density (DSTU ISO 2811-1) | 1.36 ± 0.02 g/сm3 (Base, component B) 1.12 ± 0.02 g/сm3 (Activator, component А) 1.3 ± 0.02 g/сm3 Mixture A+B) |

| Hardness (DSTU ISO 1522) | minimum 80 sec. , Konig pendulum |

| Gloss (DSTU ISO 2813) | Glossy. Minimum 60 GU at 60° |

| Wet-scrub resistance, microns (DSTU ISO 11998) |

< 1 microns (Elcometer abrasion tester, 200 cycles) |

| < 80 mg (Taber abrasion tester, 1000 cycles, 1 kg) | |

| VOC content (ISO 11890) | < 20 g/l |

| Warranty period | 24 monthes from the date of manufacturing (at the temperature from +5 °С to +35 °С) |

| Packaging | 3 kg (2,5 kg Base + 0,5 kg Activator) 12 kg (10 kg Base + 2 kg Activator) |

Gloss

Color

Application instruction

1. Surface preparation

The surface must be dry and thoroughly cleaned, ensuring it is free from dust, dirt, corrosion, mold, cinders, oils, grease, and other contaminants, as well as peeling paint coatings. We recommend using mechanical (a scratcher, a wire brush), thermal (hot air fan, infrared radiation), or chemical (solutions for paint removal) methods. You should avoid using methods that can damage the base surface.

The mineral-based surfaces must be hard without fragile parts or edges. Remove thoroughly all contaminations: remove efflorescences mechanically; areas infected with mould or fungi must be removed obligatorily: first, mechanically and then treat the surface with antiseptic for mineral surfaces TM "Farbex". Previously coated hard surfaces must be polished and dusted off.

Ceramic tile must be cleaned of old sealer, grease, dust and other contaminants. If there is paint or varnish shall be removed using a polisher or other tools to clean the surface.

Metal surfaces are treated manually with tools or abrasive jet cleaning. Remove grease with universal thinner TM Maxima and prime it.

2. Priming

Mineral surfaces, which create no dust (concrete, tile, stone), need no priming, but the surfaces with adhesively weak particles must be primed with a primer concentrate 1:10 Aqua Primer TM Maxima.

Metal surface - quick drying anticorrosion primer TM "Maxima".

3. Applying

Before you start working with the product, stir the BASE in the original container thoroughly. Layering is not a defect. Then mix it with the ACTIVATOR in a ratio of 5:1 (mass-based) before you have a homogeneous condition. Mix with a mixer or a drill with a special pod with low rotation for 2-5 minutes, avoiding foam formation.

Do not mix with other products and (or) solvent-based diluents!

Ready-to-use enamel shall be used for 1 hour (at +20 °C) from the moment of preparation!

Apply the product at the temperature of the air and the surface from +10°С to +30°С and relative air humidity less than 80%. The life period of the mixture and drying period can change depending on the temperature conditions at the time of application and relative air humidity.

We draw your attention to the following: if you want to avoid differences in shades, the finishing coat shall be applied with the product of one batch. If you use the product of different batches, you have to mix them in one container.

Remember! Mimeral surface are porous, so the consumption of the product and quantity of coats can increase. Apply the enamel in a continuous manner and in one direction keeping the same consumption of the product.

Apply the enamel in 1-2 coats with a brush, a roller or a spraying gun. After applying the first coat, check if the surface is fully coated, especially on ends or difficult-to-reach spots, which must be thoroughly coated.

Two-component epoxy enamel can be applied by following methods:

|

Application method |

Quantity of diluant |

Recommendations |

|

Airfree spraying |

0 – 10 % |

Nozzle / jet: 0.017" - 0.023" Pressure: 15 MPa (≈ 150 bar) |

|

Pneumatic spraying |

0 – 10 % |

Nozzle / jet: 2,0 - 2,5 мм Pressure: 0,3 – 0,5 MPa (≈ 3 - 5 bar) |

|

A brush |

0 – 5 % |

A plain brush of type "Euro" or "Standard" |

|

A roller |

0 – 5 % |

A paint roller of type "Velour" or "Multicolor" with a long nap 6-11 mm |

The tools must be recommended for water-based products.

We recommend using a cuvette together with a roller for homogeneous spreading. Attention! For a smoother surface, use a roller with a shorter nap. Consider that a short nap lessens the consumption of the enamel.

When you use the spraying method of application, use the exploitation manual. Airfree spraying is the best option for this method. The reason is that when you use a pneumatic spraying gun, you may need to dilute the product to the recommended maximum, which can affect the thickness of the coating or create runs. Spraying is recommended for painting horizontal surfaces only.

The product must be filtered (250-400 microns) before use.

For quality coating you must have some skills for application, especially if you use a professional tool.

Compatibility with other coatings

Depending on the terms of exploitation, the enamel can be used with various primers and finishing coatings. The examples are set below. For more detailed information, call the specialists of the POLYSAN company.

A previous coat - acrylic and epoxy water-borne article, alkyd-based and acrylic solvent-based materials.

A subsequent coat - epoxy water-based products.

Compatibility of the products is recommended to be tested on a small area.

References

The walls in the shelter are painted with Mattalatex Farbex latex paint and Farbex rubber …

Flow calculator

Consumption standard of 1 layer

When calculating the area to be painted, you need to subtract the area that will not be painted. (windows, doors, etc.)

Paint consumption may vary depending on dilution and uniformity of application of the paint.