Specification

It has a wide range of colors. It is easy to apply and form a texture. It has advanced adhesion to the surface. It is elastic, washable and resistant to mechanical load. It covers small defects of the surface and hides tiny cracks. The coating is resistant to fungi and mould and to weather effects (precipitations, UV radiation, moisture, temperature fluctuation).

Sphere of application

It is intended for finishing coating with a "mosaic" pattern on concrete, lime-cement, gypsum and other mineral surfaces, chip wood boards, MDF, plywood and OSB boards inside and outside premises. It is recommended as a decorative and protective coat for socles of the buildings and constructions, for facade insulating systems and for decorative coating of walls in the premises with moderate and advanced humidity.

It is intended for horizontal surfaces affected by water.

Content

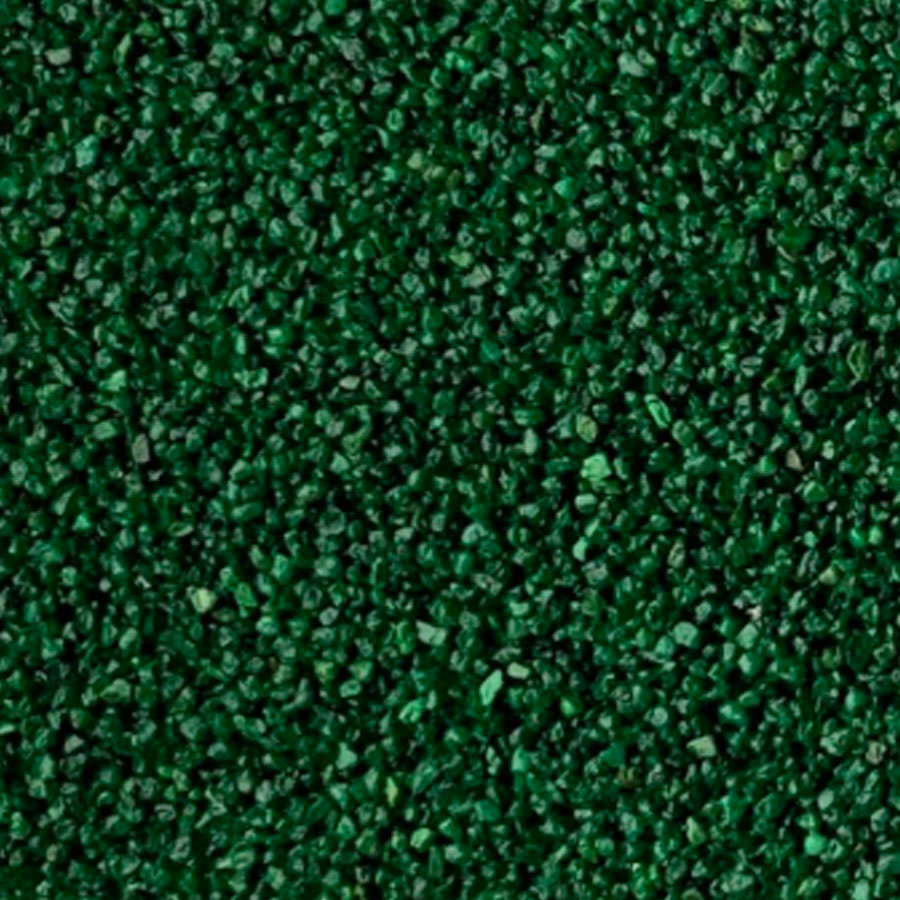

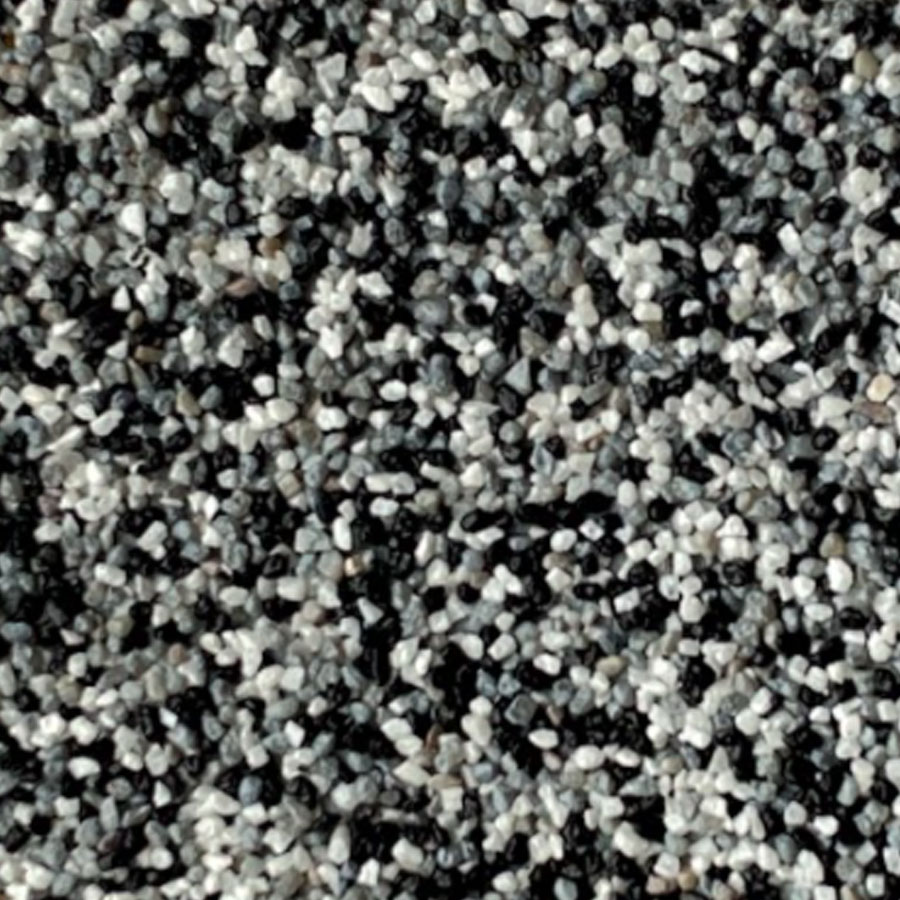

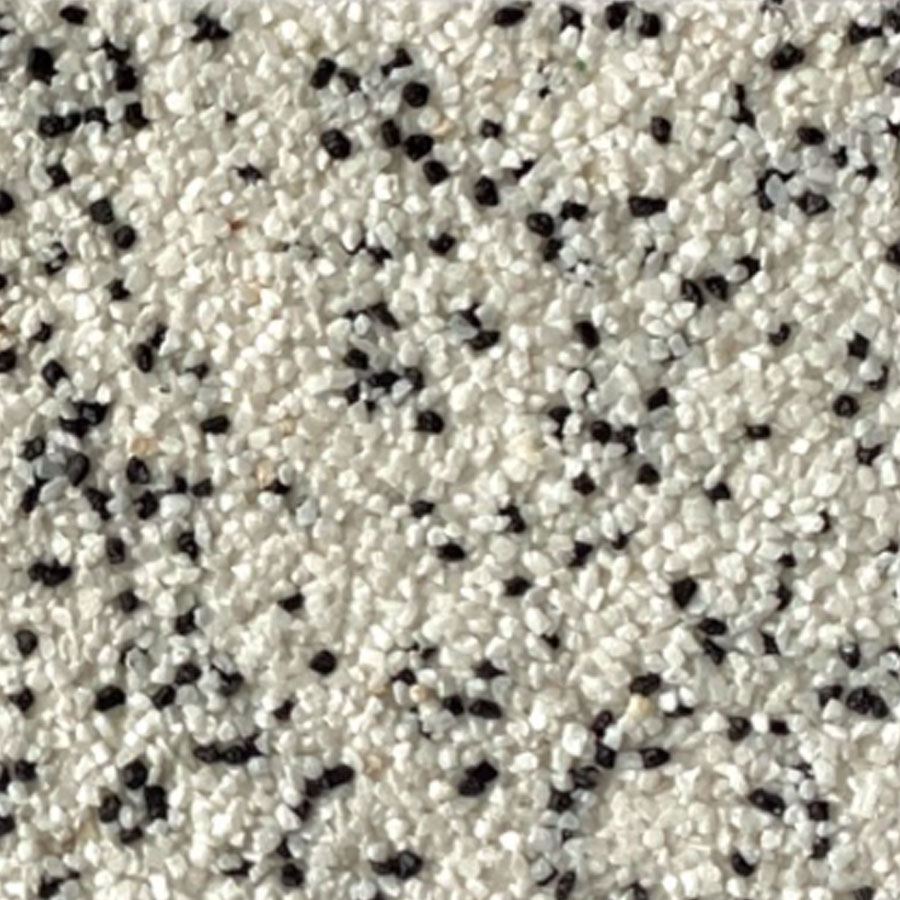

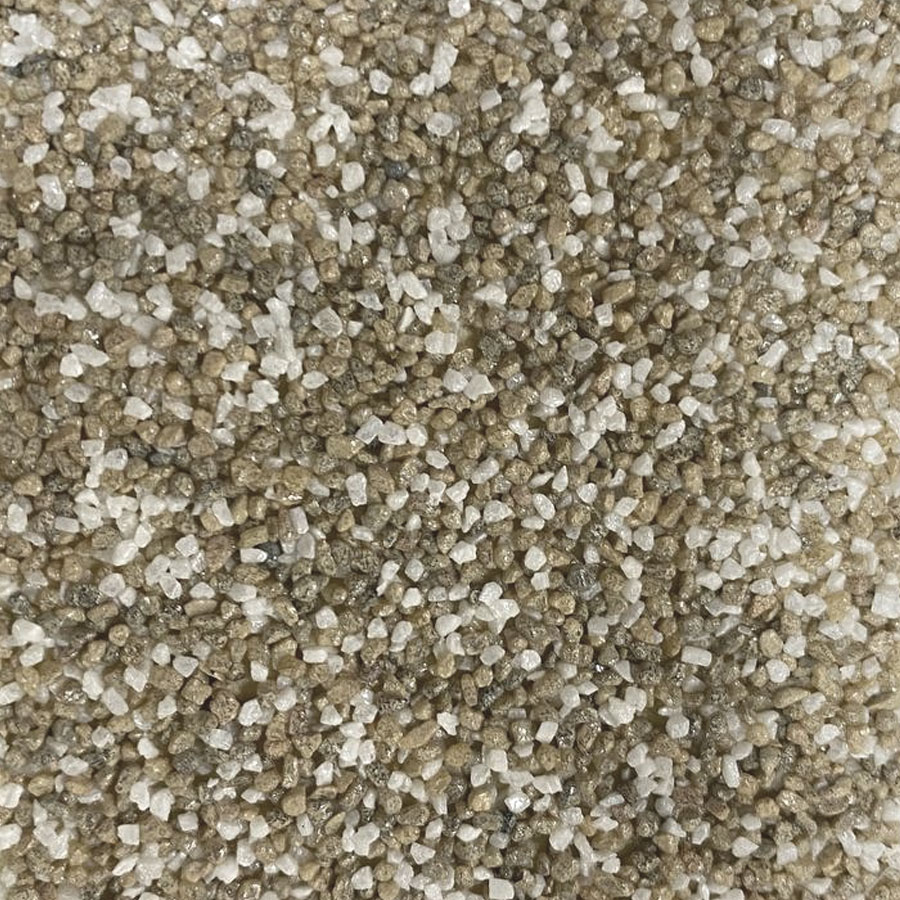

2. Filler: Colored sand (quartz or marble) of definite fraction and color.

Technical data

| Consumption standard of 1 layer | 4,5 - 5,5 kg/m2. Definite consumption of the product depends on the condition and roughness of the base surface and/or skills of a performer. Definite consumption is specified with the test trial. |

| Thinner | water. After mixing the components (binding substance + filler), the plaster is ready to use and requires no dilution |

| Application | Apply and flatten with a trowel or a stainless spatula. |

| Drying period (23 °С, 50% RH) | ab. 18 hours. After application of the plaster the surface shall not be effected with precipitations or subzero temperatures during 24 hours. Complete drying of the coating is in 14 days. |

| Solids content (DSTU ISO 3251) | 78±2 % |

| Density (DSTU ISO 2811-1) | ≈ 1,75 g/m3 |

| Gloss (DSTU ISO 2813) | Not defined, (not defined, G0, DSTU EN 1062-1) |

| Dry film thickness | It corresponds 1,5 grain size, ab. 2,5 mm, for one layer coating (> 400 microns, E 5 ,DSTU EN 1062-1) |

| Particle size | maximum 1500 microns, (hard-grained, > 1500 microns, S3, DSTU EN 1062-1) |

| Vapor permeability (EN ISO 7783-2) | minimal 20 g/(m2*24hours), (medium, V2, DSTU EN 1062-1) |

| Water permeability (DSTU EN 1062-3) | maximum 0,1 kg/(m2*hour0,5), (low, < 0,1 kg/(m2*hour0,5), W3, DSTU EN 1062-1) |

| Marking acc. to the DSTU EN 1062-1 | G0|E5|S3|V2|W3|A0|C0 |

| Non-volatile matter by volume (DSTU ISO 3233) |

61,5±2 % |

| Warranty period | 24 months from the date of manufacturing of acrylic binding substance |

| Packaging | 14,7 kg of ready to use plaster after mixing all components |

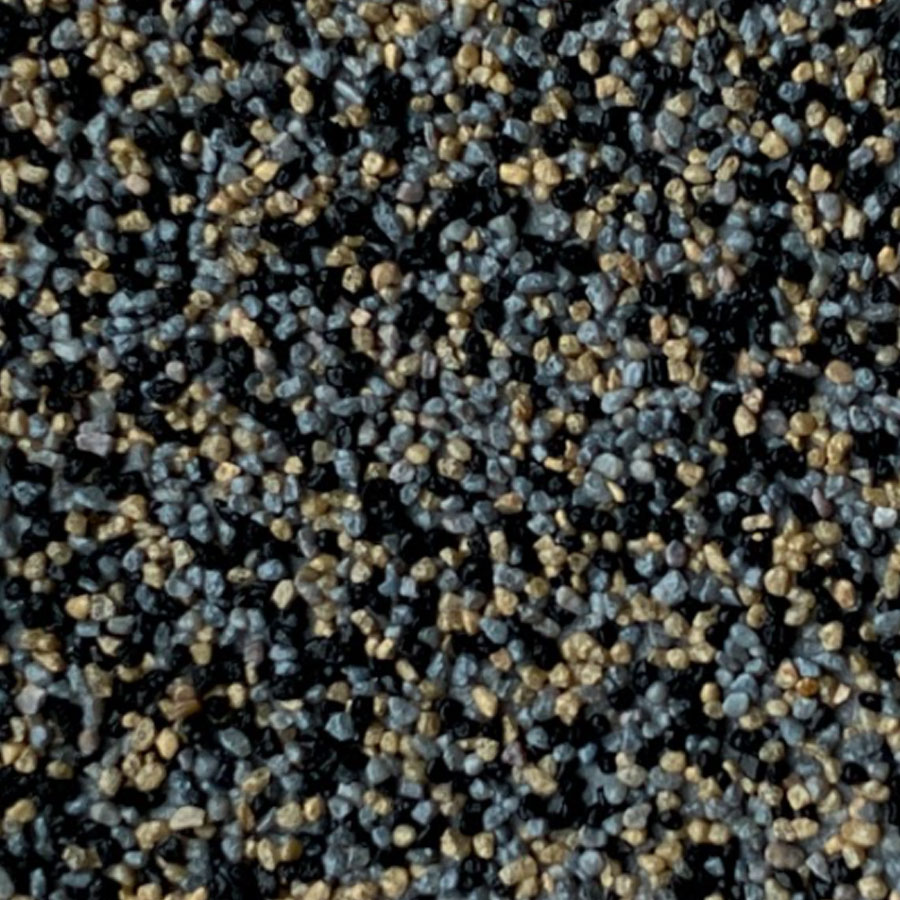

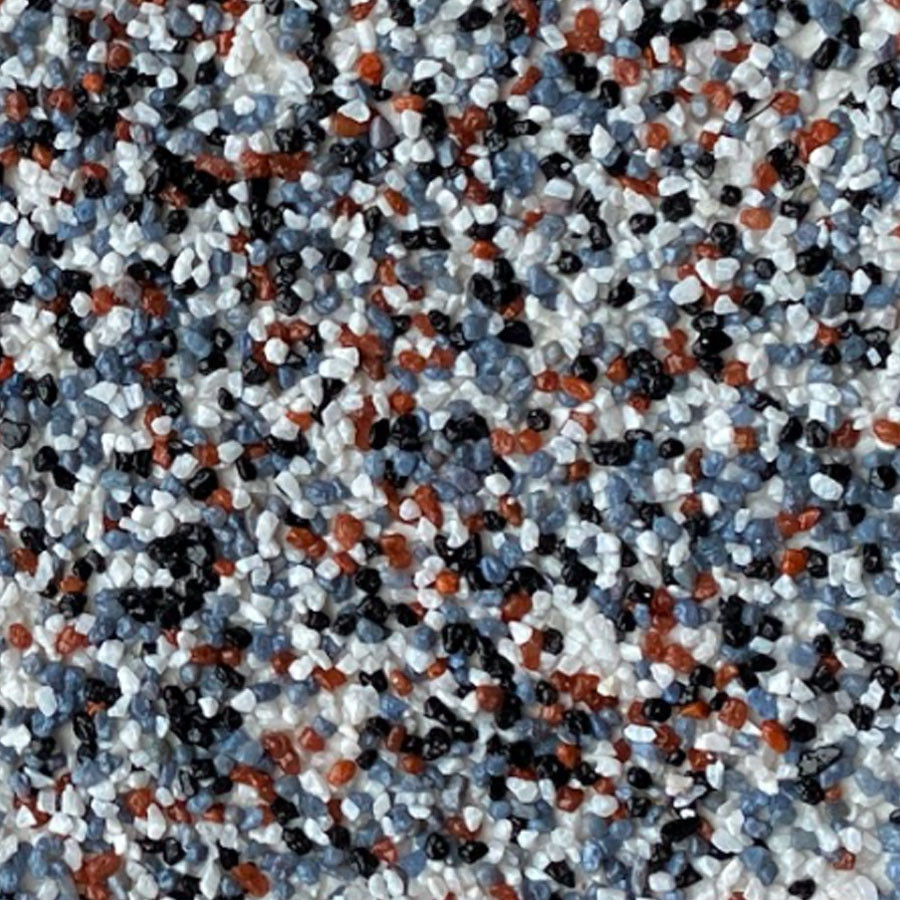

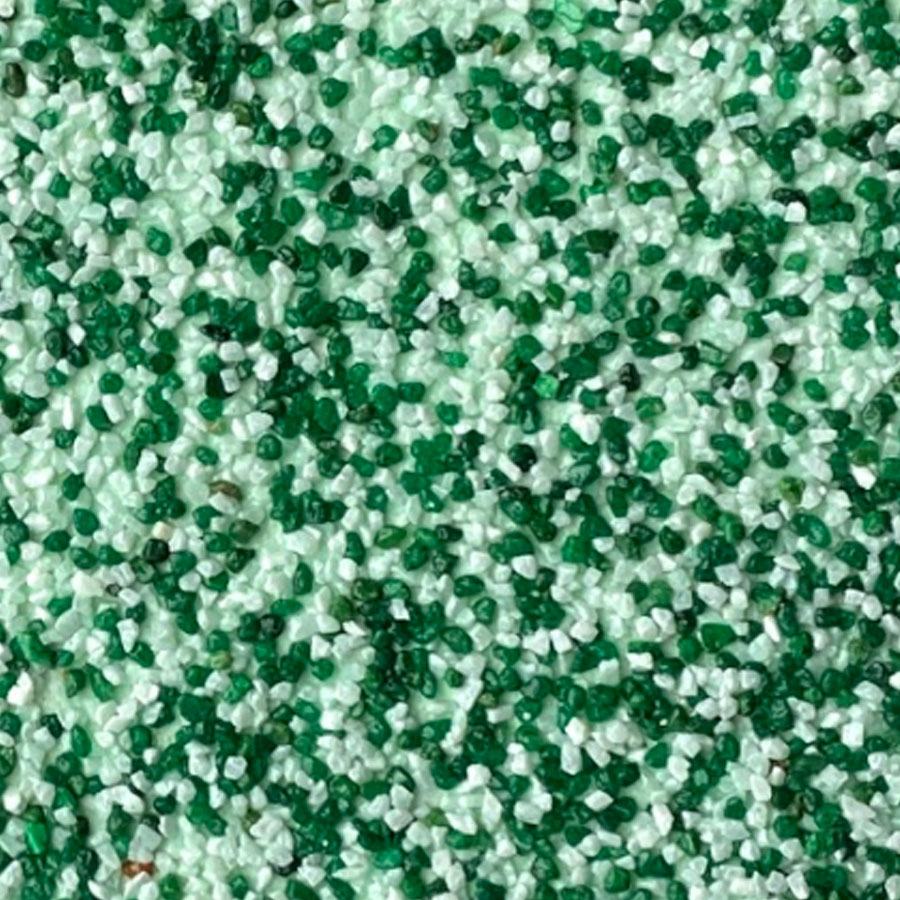

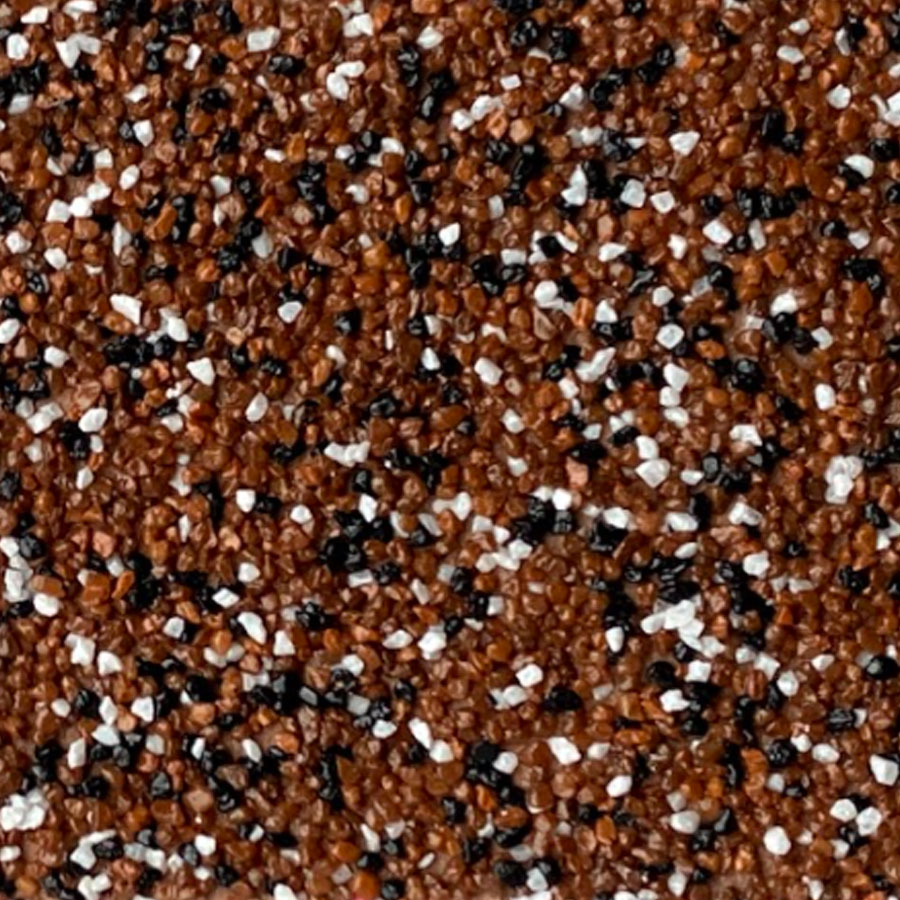

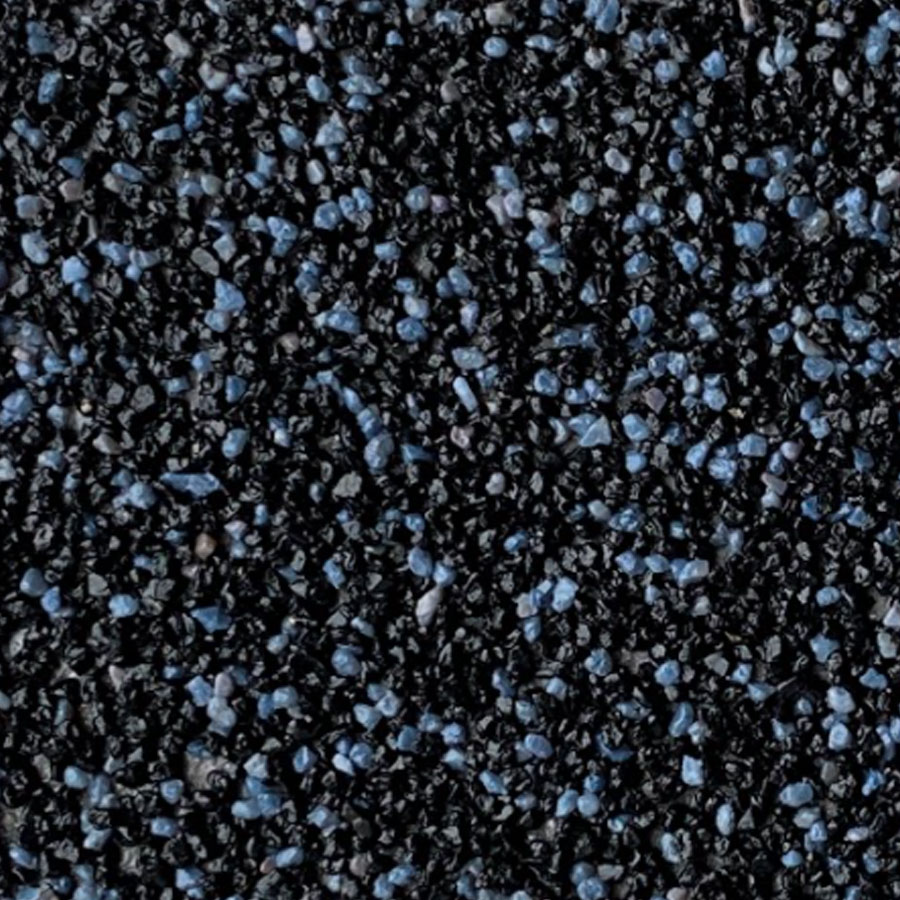

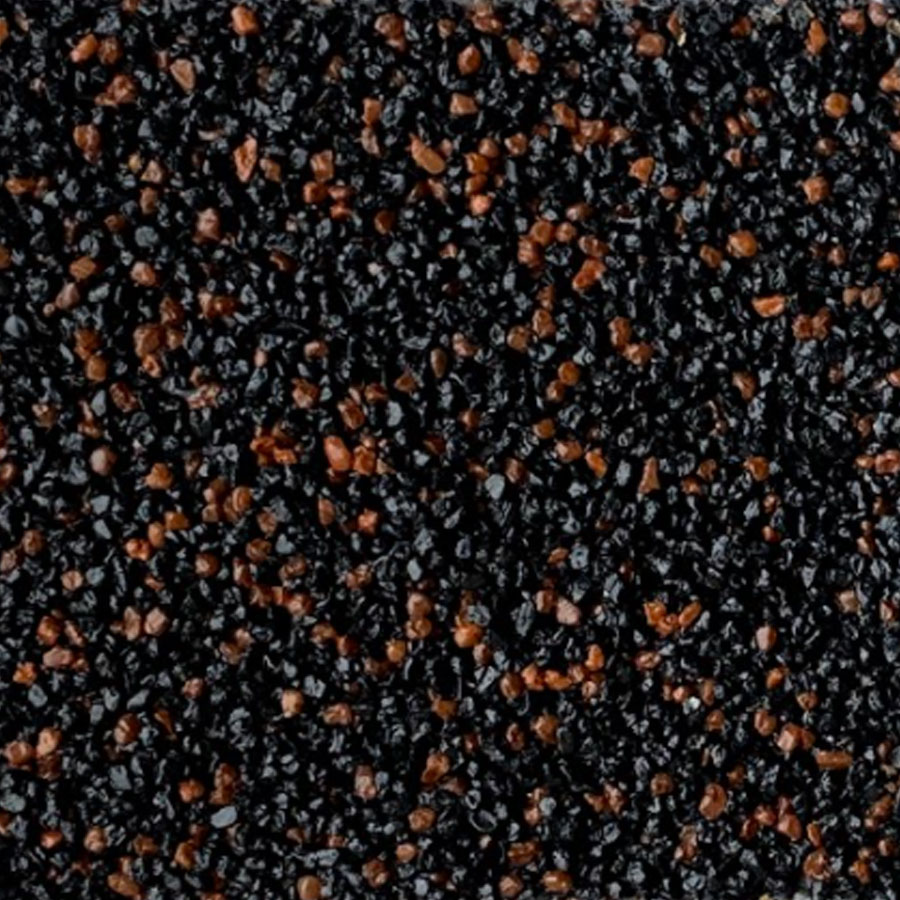

Color

Application instruction

-

1. Plaster preparing

In order to receive ready-to-use plaster, add the necessary quantity of colored sand (Farbex) to the bucket with a binding substance (premix) for acrylic decorative plaster "Mosaic" TM "Farbex". Mix it with a shaker (a kneader).Ratio of components: 4.7 kg of acrylic binding substance for 10 kg of sand. It is recommended to mix with slow speed without fluffing up. It is not recommended long-lasting mixing (more than 5 minutes).

2. Surface preparation

The surface shall be dry and hard, thoroughly cleaned from dust, dirt, grease and other contaminations before application. Fragile surfaces and dirty areas shall be cleaned in a mechanical way, with a spatula or a wire brush. After that remove the dust. The newly applied coating of the plaster shall not be treated during 2-4 weeks. Defects of the surface shall be removed with a plaster TM "Farbex". Corrected areas shall be well dry and hard. The surface shall be polished, the abrasive dust shall be removed. Use antiseptic TM "Farbex" for protection against mould and fungi. It is necessary to use deep-penetrating primer TM "Farbex" to level the absorbing ability of the surface and improve adhesion to the mineral surface.

3. Priming

It is necessary to apply a coat of universal paint-primer TM "Farbex" or an adhesive primer "Beton-Kontakt" TM "Farbex" depending on the type of the surface. The pain-primer or "Beton-Kontakt" shall be colored according to recommended from the catalog.

4. Applying

Stir the plaster with low-speed mixer for 1-2 minutes before application.

Apply the product 1 coat of the product with a trowel or a spatula from down to up direction. Freshly applied mixture shall be flattened (smoothed) with a metal trowel till the thickness of the coating of 1,5 of the grain size.

Make smoothing in one direction, make sure that the surface is flat and have no runs of the product, repeating on the same place and thick layer of an application. It is recommended to clean the tools from time to time during application. Control the quality of the flat coating surface with side lighting immediately after application. Found defects shall be corrected before the plaster gets dry.

Apply the plaster with in the same way and the same tools on large areas.

Colored filler, which is used in the plaster, can have a deviation in color, that is why it is recommended to use the product of the same batch or make advanced mixing of the necessary volume of the product.

It is recommended to perform the application continuously "from corner to corner" or within decorative elements, with the method "wet on wet". If stop it is recommended to glue a masking tape on the finishing line, which shall be removed with the rest of the freshly applied plaster after its flattening. Start further work from the place of stop.

The film of the plaster can become slightly hazy if it's occurred with the long-lasting effect of water. It disappears when dries.

The temperature of air and the surface shall be from +5 °С to +30 °С, relative air humidity less than 80%. Do not apply the plaster under direct sunlight, strong wind and high air humidity.

5. Tool cleaning

Wash thoroughly the tools with water after work. Don't let it dry.

References

Частина фасаду будівлі оштукатурена акриловою декоративною штукатуркою «Мозаїка» Farbex (колір F49).

Для оздоблення фасаду використовували декоративну акрилову штукатуркою “Баранець” Farbex заколорованої у кольори NCS S 3060-G70Y, …

Acrylic plasters Farbex

Acrylic plastersповністю

Flow calculator

Consumption standard of 1 layer

When calculating the area to be painted, you need to subtract the area that will not be painted. (windows, doors, etc.)

Paint consumption may vary depending on dilution and uniformity of application of the paint.