Universal Rubber Paint. Key Qualities and Applying Tips

Thousands of articles for various surfaces and purposes represent the paint products market. The most popular interior paints are acrylic and latex because they are durable and washable. Silicone paints are often chosen for insulated facades to improve their vapor permeability on the surface. People use anticorrosion enamels to protect metal surfaces against moisture and corrosion effects. It is convenient to coat wooden surfaces with acrylic enamels because they dry quickly and have no strong odor, so it is widely used for indoor work. Rubber paint is a product, which was developed by POLYSAN specialists to solve several tasks in finishing work.

Universal Rubber Paint TM Farbex is a unique water-based product, which was named after its feature to create a highly elastic film on the surface. Due to its unique properties, Rubber Paint is a universal decision for building facades, roofs, socles, water pipes and gutters, brick and stonework, pillars, fences, living premises, kitchens and bathrooms, sports complexes and trade halls.

Key Qualities of Universal Rubber Paint

High elasticity is a key feature, which differs Rubber Paint from a number of usual paints.

It can change its form and size without damage or spoil. This property is especially important in cases, when the surface, where the paint is applied suffers from various deformations like widening, pressure, and binding. For example, under temperature fluctuations, to avoid cracks or peeling from the surface.

Matt coating effectively hides micro-cracks on the coated surface. Rubber Paint has high adhesion to mineral, wooden and metal surfaces. The paint can be also applied on surfaces, that were previously coated with alkyd-based and oily paints.

Rubber paint demonstrates advanced resistance to water, repeated washing, UV radiation, and weather effects. If you prepare the surface correctly and follow all directions, the coating keeps its protective and decorative properties for up to 7 years.

The Surfaces, where Universal Rubber Paint can be Applied on

- Tile and ondulin

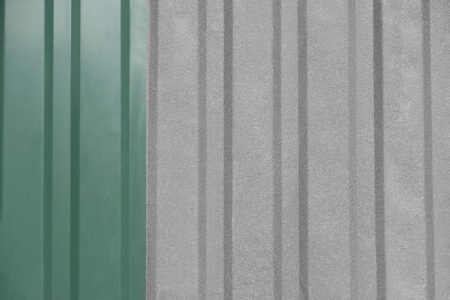

- Galvanized still, aluminum, corrugated boards

- Primed iron

- Concrete and foam concrete

- Brick work and stone work

- Plasters and stuccos

- Ply wood, MDF, wood chip boards, plywood, chipboard, CPB, wood

- Gypsum boards, paper, fiberglass wallpapers

Preparation of Various Surfaces Before Applying Rubber Paint

The guaranty to have a desired result of coating is to follow all directions concerning preparation of the surface and using of the paint product.

Slate, ceramic or mineral tile

Products used for roof coating constantly suffer from weather effects, which is why it is necessary to prepare the surface for coating carefully.

Before coating the surface shall be clean. Wash the roof manually or use any high-pressure washing facilities. Use antiseptic conctentrate for mineral and wooden surfaces TM Farbex to prevent moss and fungi creation. Check if there are any damages, cracks and other defects on the tile or slate surface. It is also necessary to check that repairing materials are eligible to be coated with water-based products. Make sure that the surface is completely dry before applying the rubber paint.

Tile and slate are quite rough materials, that’s why priming before coating is not necessary. But it is necessary to apply a preparing coat of the paint in order to fix small particles and dust on the surface. Dilute the paint with water for this purpose (max. 10%) and apply a thin coat on the surface. This step is necessary also to improve adhesion of the paint basic coats the surface.

Corrugated sheeting, zincked metal, aluminum

It is necessary to clean the surface from corrosion, grease and oily contaminations to provide maximum resistant coating. In case of a great number of corrosion deposits on the metal, it is recommended to change it. Oily and grease contaminations are better removed with special alkali solutions. If the surface was coated with alkyd-based or water-based coatings, remove them completely. Composed or powder coatings without visual defects are not obligatory to remove. Wash thoroughly cleaned surfaces with clean water under pressure and wait until the surface becomes totally dry.

We recommend prime the surface with quick-drying anticor primer TM Maxima to provide the coating maximum exploitation resistance and durability.

Mineral surfaces

Before applying the rubber paint on mineral surfaces, they shall be cleaned from chalk and lime whitewashing, grease, oily and other contaminations, dust, old paint coatings, wallpaper, polymeric adhesives, runs of construction solutions and composites. Clean thoroughly the areas affected with mould or fungi mechanically and then treat with antiseptic conctentrate for mineral and wooden surfaces TM Farbex. Make sure that there is no fragile parts or edges on mineral surfaces after cleaning. Make renovation with products, which are suitable for waterborne coatings. Dry the surface before coating. Previously coated mineral surfaces must be treated with deep penetrating water dispersion acrylic primer «Super Base» TM Farbex.

Ply wood, MDF, wood chipboards, wood, cement chipboards

Clean carefully wooden surfaces from dirt, dust, oily or other contaminations and paint coatings, that become loose and start peeling off. Bluestein, mould or fungi shall be removed mechanically and then treat wood with antiseptic for wooden surfaces TM Farbex. Splinters, uneven areas and other defects can be corrected with Putty for parquet, wood and mineral surfaces TM Farbex. Finished surface shall be polished and dusted off. If wooden surfaces were not treated before, they shall be obligatory primed with Acrylic wood-protective primer TM Maxima.

The surfaces coated with alkyd-based, oily, water-based paints, wallpapers

The surfaces, which were previously coated with oily or alkyd-based paints must be sanded to the matt condition and wash with a weak solution of detergent for better adhesion. Rinse the surface with water and dry it. The surfaces, which were previously coated with water-based paints, shall be slightly treated with sandpaper and dusted off. Coat the wallpapers after the glue is completely dry. Make sure that the wallpapers stick firm to the walls. It is not necessary to prime previously coated surfaces and wallpapers before coating.

Hints for applying the rubber paint correctly

Before using the rubber paint make sure, that the base surface is completely dry after preparation. Otherwise, the paint will peel off from the surface. Before you start applying the paint, it is necessary to stir it and if it is needed filter or dilute with water. Maximal dilution shall not exceed 10% of the paint`s volume. Excessive dilution lessens adhesion and coverage rate.

Normally the rubber paint is applied in 2-3 coats. The first coat is the basic one. This step is when you carefully coat all areas that are difficult to reach. Apply a subsequent coat after the previous one is fully dry but not earlier than 4 hours. Finishing coat makes the surface homogeneous, improves decorative and protective effects. Paint’s coverage rate can differ depending on the type of surface. Porous surfaces demand more paint to create a homogeneous coating surface.

Apply the rubber paint at the temperature of air and the surface from +10 °С to 24 °С and relative air humidity less than 80%. Do not apply the paint under direct sunlight, strong wind, frost and precipitations. After the paint is applied in shall not be affected by subzero temperatures and precipitations during 24 hours. The coating becomes completely hard and eady for exploitation after 28 days.

Hints for rubber paint tinting

A set of ready from the factory colors of Universal Rubber Paint consists of 17 articles. Besides, you can tint the paint manually in other colors with Waterborne concentrate pigment «Farbex Color» and other tinting pastes or by using a tinting machine according to RAL, NCS and other color rates. The rubber paint is manufactured in following bases:

- Base A. It is intended for use as a ready-to-use coating of white color or for tinting in pastel light shades and hues of medium saturation.

- Base C. It is intended for tinting in saturated colors. Base C is not used without tinting.

To avoid differences in shades of colors, when you apply a finishing coat, we recommend using the product of the same batch (as the paint, so is the pigment concentrate).

21.05.2024