How to paint metal entry doors and what paints to use?

The appearance of the entering metal doors plays an important role when you have the first impression of the house. However, as time passes, the metal door can lose its initial gloss because of the influence of outer factors, wear, or corrosion. Coating the metal entry door is not the only way to renew its appearance but also to protect it against corrosion and prolong its duty period. Preparing the door correctly and choosing instruments and materials is necessary for a long-lasting and aesthetic result.

Types of enamels for coating metal doors

The appearance of the entering door plays an important role when you have the first impression of the house. However, as time passes, the metal door can lose its initial gloss because of the influence of outer factors, wear, or corrosion. Coating the metal entry door is not the only way to renew its appearance but also to protect it against corrosion and prolong its duty period. Preparing the door correctly and choosing instruments and materials is necessary for a long-lasting and aesthetic result.

Types of enamels for coating metal doors

There are several types of paint products, which are used for paint coatings:

Anticorrosion enamels 3in1

Metal enamels 3in1 are universal products, which functionally combine adhesive primer, anticorrosion protection and finish enamel. The advantages of those enamels are:

- Adhesion. The enamel has a high adhesion to metal surfaces.

- Resistance. The enamel creates a coating, which is resistant to water, weather effects, industrial oils, and domestic detergents.

- Anticorrosion protection. The enamel creates an anticorrosion film on the surface, which protects the metal against moisture and air, corrosion emission.

- Quick drying. Drying period of anticorrosion metals is measured from 1 to 8 hours, so you can apply several coats of enamel during 24 hours.

When you use 3in1 metal enamels, your advantages will be the safe of time and efforts, because you have no need to apply primer and anti-corrosion products. Besides, they create a hard and durable coating, protecting metal doors against outer impacts and providing an attractive esthetic look. Coated with anticorrosion enamels, the surfaces show resistance to weather effects, water, industrial oils and domestic detergents.

The enamels have several options of finish coating: graphite, hammered or smooth.

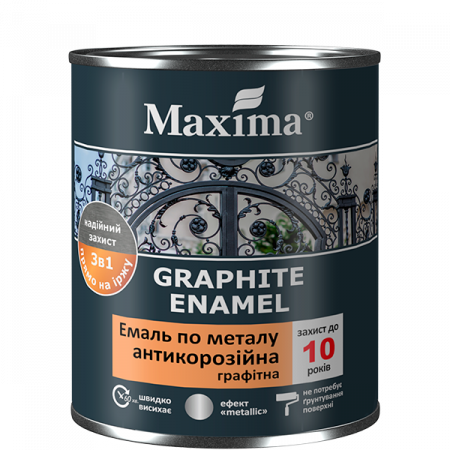

Anticorrosion metal enamel 3in1 TM Maxima, graphite creates decorative relief texture with a “metallic” effect, visually masks and equalizes surface imperfection (places of joints, locally renovated places, scales and alike). The coating becomes a matt elastic film with high anti-corrosion properties.

Anticorrosion metal enamel 3in1 TM Maxima, hammered creates an anticorrosion film with a nacre hammered effect on the surface. After drying the surface looks like it was hit with a hammer much many times. That is the source of its name “the enamel with hammered effect”.

Anticorrosion metal enamel 3in1 TM Maxima, smooth creates a smooth highly glossy anticorrosion film.

In general, the metal enamels 3in1 are a convenient and effective decision for coating metal doors, providing protection against corrosion, hard coating and stylish appearance.

Alkyd enamels.

An alkyd metal enamel is one of the most widely used options for coating metal surfaces including entry doors. The enamel creates a protective coat, which provides durability and an esthetic appearance to metal products. We refer to the advantages of alkyd enamels these:

- Hardness and resistance. Alkyd enamels provide good protection against corrosion, UV radiation, weather effects and mechanical damages like scratches and abrasions.

- Wide choice of colors. The enamels are available in various colors that allows choosing appropriate options for your building design.

- Easy-to-apply. Alkyd enamels can be applied with a brush, a roller or a spraying gun, which makes the process of coating quite simple and convenient for application in domestic conditions.

- Durability. After application and drying alkyd enamels create a hard and durable coating that keeps its appearance and quality for many years.

You find a high-quality alkyd enamel TM Maxima in our assortment. It is outstanding with its high gloss degree and resistance. It bears temperature fluctuation and demonstrates perfect weather resistance indicators. It is easy to apply. It has good adhesion and coverage. It is resistant to washing with detergents and disinfectors. It is represented with wide ratio of colors from the plant.

Before you start coating metal doors with alkyd enamels, it is obligatory to prepare the surface by cleaning it from old paint, dirt, and corrosion. It is also obligatory to apply an anticorrosion primer for better adhesion and to prevent corrosion from appearing.

Acrylic enamels.

Acrylic enamels for metal is a modern and effective decision for coating metal surfaces including entry doors. They have a number of advantages, which make them a popular option for many projects:

- Perfect adhesion. Acrylic enamels provide perfect adhesion with metal surfaces and guarantee hard and durable coating.

- Resistance to weather effects. They have high resistance to UV-radiation, moisture, high and low temperatures, that makes them suitable not only for interiors but also outside.

- Quick-drying. Acrylic enamels usually dry quickly, which allows the paint project to be finished in a short time.

- Wide range of colors. They are available in various tones, which allows you to choose an appropriate option for any design or style.

- Acrylic enamels have no acid smell, so the work with them become more comfortable.

Powder enamels.

Powder enamels for metal are popular and effective decisions for coating metal surfaces including entry doors. Powder coatings are remarkable by their hardness, resistance to the effects of the environment and the possibility to create various colors and textures. However, it is impossible to apply powder enamels at home without dismantling the doors. Powder enamel application requires electricity, when with the electric discharge you apply a thin layer of powder on the prepared metal surface and locate the doors in the premise at a temperature of about 200 ° С. There the powder will melt and create a homogeneous coating.

The advantages of powder enamels are their high resistance to abrasion, strikes, UV radiation and chemicals. It has also a perfect adhesion to metal surfaces. As a result, you receive a smooth and attractive coating, which is also highly durable.

How to prepare metal doors for coating

Let’s dwell on the basic steps of preparing metal doors before painting, which help you reach a professional result even if the work will be done by not a master and in domestic conditions:

- Clean the surface. Use a brush or a sponge with a soap solution to remove contaminations, dust, oil and other contaminations from the door surface. It is a crucial step because any grease or dirt rests can prevent enamel or primer adhesion.

- Removing old coatings from metal surfaces. There are three basic options to remove old paint coatings: mechanical, chemical, thermal. Decide which method you will use: an effective method for one metal will not work with another. Find a detailed information about each of the methods in our article “Four rules of quick and reliable coating of metal”.

- Remove corrosion. There is a list of effective methods of clearing, which allow removing corrosion and renovating the original look of metal surfaces. We recommend you read about it in our article “Four rules of quick and reliable coating of metal.” Sometimes it is not necessary to remove corrosion from the surface. If the layer of corrosion doesn’t exceed 100 microns, we recommend you coat the surface with anticorrosion enamel 3in1. It will help you save money and time for coating.

- Priming. We recommend you to use our new product Quick-drying anticorrosion primer TM Maxima before applying acrylic enamel for wood and metal TM Maixma or high-quality alkyd-based enamel TM Maxima. Apply a homogeneous coat of primer all over the door. It will help improve the adhesion of the paint to the metal surface and prevent corrosion. Let the primer dry after applying according to the directions. If you have enamels 3in1 – they require no advanced priming with any special product.

Painting metal doors

When the primer gets dry, you may paint the door surface, following the manufacturer’s directions for the quantity of coats and timing for subsequent layering. We recommend using a spraying gun: the spraying effect allows reaching homogeneously applied paint and is more economical.

From the other side, a spraying gun coats a metal with thinner coat, if we compare it with coating with a brush. That is why, when you work with a spraying gun, you have to apply the door with 3 coats of paint, when using a brush or a roller 2 coats are enough.

One more undisputable advantage of using a spraying gun is the absence of runs and marks, which is a usual thing when you use a roller or a brush.

Start painting from the top of the door and gradually get down. If you decide to apply the paint with a brush, shift the direction of strokes when you apply every subsequent coat. If you apply the paint with a roller don’t work on fresh painted areas. The layers are applied with not very broad lines from up down and beginning from the left edge move slowly to the right edge.

Subsequent coats are applied only after the previous have been dried. If there are runs on the coating, let it dry and cut them off with a razor or a utility knife. After that polish the surface. Eventually, apply one more layer of the coating.

An important thing is to remember about safety when you work with enamels and chemicals. Use protective gear, respirator and goggles, to escape harmful consequences for your health.

Following these recommendations, you can easily and effectively renew metal entry doors, providing them a fresh look and protection against outer effects for a long period.

Read more

25.04.2024