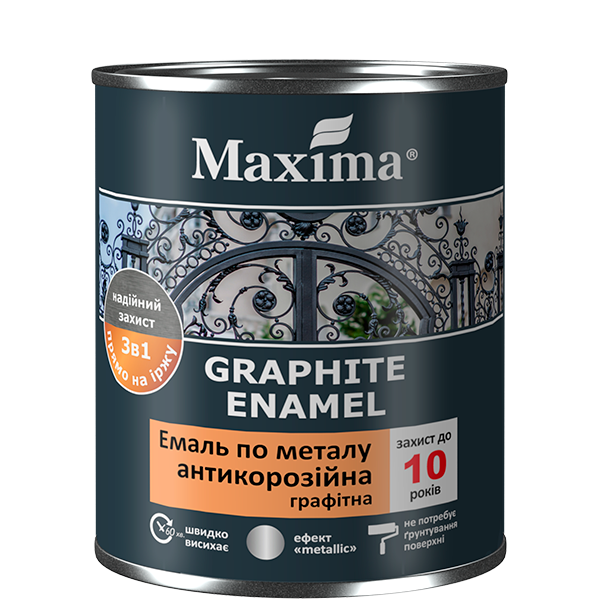

Maxima

Hammer Enamel 3 in 1

Specification

Hammer enamel 3in1 TM Maxima, which functionally unites adhesion primer, anticorrosion protection and finishing enamel in it. It creates on the surface anti-corrosion film with pearly hammer effect, which protects the surface of the metal against moisture, air and corrosion effects. It requires no preliminary treatment with special products to remove the corrosion and undercoating. It creates the coat, which masks small defects of the surface. It is resistant to water and weather effects, UV-radiation, industrial oils, domestic detergents.It dries quickly, that is why it is possible to apply several coats of enamel during a day. The enamel has high adhesion to the base surface.

Sphere of application

It is intended for protection against corrosion and decorative coating of metal surfaces (clean, coated, of covered with corrosion) of steel, iron, stainless steel, colored metals (fences, gates, building constructions, farming machinery, metal boxes, lathes, metal window frames and doors, elements of decoration, etc.), and also for wooden surfaces indoors and outdoors.

Content

Technical data

| Consumption standard of 1 layer | 80-125 g/m2, depending on the way of application and type of surface. |

| Thinner | Universal thinner ТМ Maxima, up to 10 % of the total mass of the enamel if applying with a brush or a roller and up to 30% if applying with a spraying gun. ATTENTION! Do not use white spirite, solvent or others similar products. |

| Application | Apply with a roller with short hair or a spraying gun. |

| Drying period (23 °С, 50% RH) | 4 hours. Drying period increases if the temperature is getting down and relative air humidity is getting higher. |

| Solids content (DSTU ISO 3251) |

53,5±2 % |

| Density (DSTU ISO 2811-1) | 0,98-1 g/сm3 |

| Gloss (DSTU ISO 2813) | ≈ 80 GU (at 60º) |

| Non-volatile matter by volume (DSTU ISO 3233) |

47,5±2 % |

| VOC content (ISO 11890) | 460±10 g/l |

| Warranty period | 36 months from the date of manufacturing. |

| Packaging | 0,75 l, 2,5 l (10 и 20 l - if preodered) |

Gloss

Color

Application instruction

The condition for receiving a desired result is following directions for using the paint product and preparing the surface.

1. Surface preparation

The surface must be dry, thoroughly clean of dust, dirt, mould, corrosion, oily and other contaminations, and peeled paint coatings till the hard base surface.

Use these methods of cleaning: mechanical (a scratcher or wire brush), thermal (a heat gun or infrared radiation), and chemical (paint-removal solutions). Avoid using a cleaning option that can damage the base surface.

Metal surfaces shall be treated manually with mechanical instruments (min stage St2) or abrasive jet sander (min stage Sa2½) according to DSTU ISO 8501-1. Degrease it with Universal diluent TM Maxima.

Wooden surfaces must be polished manually or with a polisher. Remove abrasive dust from the surface. Remove resin deposits from the surface of the wood mechanically (with a spatula or a scratcher). If wood is infected by blue stain, mould, or fungi, remove infected areas: first mechanically, then treat the wood with antiseptic for wooden surfaces TM Farbex. Correct created uneven areas with Putty TM Farbex. Polish the corrected surface and dust it off. The humidity of the wood must be less than 20%.

Hard, previously coated surfaces must be polished and dusted off. It is necessary to achieve the best adhesion of the paint product.

Before you use subordinate products (primer, adhesive, antiseptic, etc.), we recommend checking compatibility on a small area of the surface, following all recommendations and hints made by specialists.

2. Priming

The surfaces demand no obligatory priming, but for maximum exploitation resistance we recommend:

Metallic surfaces - quick-drying anticorrosion primer TM Maxima;

Wooden surfaces - wood-protective alkyd-based primer TM Maxima.

3. Application

Before application stir the enamel carefully till homogeneous condition. Dilute the enamel with a thinner till working viscosity.

Apply the enamel with a brush, a roller with short hair - 2-3 thin coats, with a spraying gun (distance from the surface shall be 15 - 20 sm, pressure - 2 atm.) - 3-4 coats with interoperation period between applications of 15 minutes.

The high-decorative coat can be achieved if the application is performed with a spraying gun!

The surface, which is going to be coated, is better to dispose horizontally to receive the best possible equal texture and color of the coat.

Apply the product at the temperature of air and surface from + 10 °С till + 25 °С, maximal air humidity 80%. Do not apply the enamel under direct sunlight, strong wind and precipitations. The surface shall not be affected by precipitations during 24 hours after application.

The coat is completely hard and achieves its properties in 14 days.

4. Tool cleaning

Clean tools with a thinner and then with warm water with detergents if necessary.

You may also be interested in

Tips

How to paint metal entry doors and what paints to use?

The appearance of the entering metal doors plays an important role when you have the first impression of the house. However, as time passes, the metal door can lose its initial gloss because of the influence of outer factors, wear, …

Як видалити фарбу з металу?

Перед фарбуванням металу, його необхідно підготувати. Одним із етапів підготовки металу є видалення старого покриття. Видалити старий шар фарби з металу можна декількома способами: Механічним. Термічним. Хімічним. Після ознайомлення з цією статей, ви будете точно знати, який із методів вам …

Enamels 3 in 1 Maxima

Емаль 3 в 1 – це емаль по металу, яка функціонально об’єднує в собі: адгезійну ґрунтовку, захист від корозії та фінішну емаль. Антикорозійна емаль застосовується для фарбування металевих, дерев’яних та мінеральних поверхонь. Завдяки своїм характеристикам, емалі по металу створюють надійний захист від корозії та надають естетичний зовнішній вигляд. Антикорозійну емаль використовують для захисту та декорування різних металевих виробів, будівельних конструкцій, сільськогосподарської техніки, металевих вікон, шаф та дверей, як всередині, так і ззовні приміщень. Основні переваги емалей 3 в 1:- не потребує попереднього застосування ґрунтовки;

- можна наносити відразу на іржу, що дозволить вам зекономити час;

- легко наноситься;

- низька норма витрати.

повністю

Hammer Enamel 3 in 1 Maxima

Молоткова емаль при нанесенні на поверхню виглядає як після безлічі ударів бойком молотка. Так пояснюється назва "емаль з молотковим ефектом".

повністю

Flow calculator

Consumption standard of 1 layer

When calculating the area to be painted, you need to subtract the area that will not be painted. (windows, doors, etc.)

Paint consumption may vary depending on dilution and uniformity of application of the paint.